Process average estimates should be performed separately for each characteristic or location on the group chart (see Calculation 1).Ĭalculation 1. To do this, operators might try a different way of positioning the work piece material in the holding fixture or find a different way to machine the dimension at location c.

#Xbar r charts manual

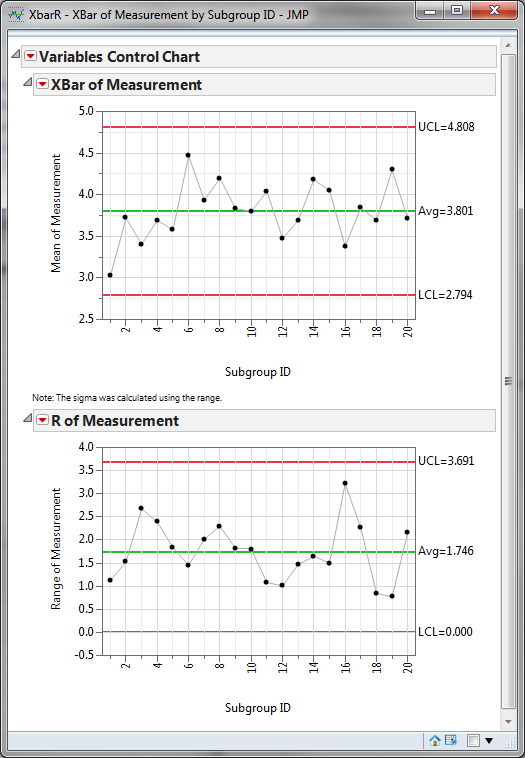

This example provides a deep dive into the manual calculations behind the group Xbar-R chart. This is why the group Xbar-R chart is selected. Although the dimensions of the poppet could also be monitored using three separate Xbar-R charts-one for each dimension-quality assurance wants to monitor the diameter using only one chart. To check the uniformity, three OD measurements arc taken on each poppet at locations a, b, and c. Therefore, uniformity of the OD is designated as a key characteristic. Rejection rates due to inconsistent ODs have been unacceptably high. Ī poppet is manufactured on a screw machine. Three OD key characteristics on a poppet. Review the following example-an excerpt from Innovative Control Charting 1-to get a sense of how a group Xbar-R chart works.įigure 1. Group Xbar and range (Xbar-R) charts help you assess changes in averages and the range of averages across measurement subgroups for a characteristic. Process Capability (Cp) and Performance (Cpk) Chart.Individual X-Moving Range (IX-MR) Chart.SPC Glossary: Quality Management Reference.Capability and Cpk Manufacturing Charts.

Statistical Process Control (SPC) Implementation.

#Xbar r charts how to

How to Choose a Manufacturing Quality Intelligence Platform.How to Sell Your Quality Management Plan.How to Use Quality Metrics to Improve Quality Management in Manufacturing.Quality Management Principles to Build Your Discipline.Digital Transformation in Manufacturing: The Role of Quality.Elevating the Importance of Quality Control in Manufacturing.Dynamic Remote Alarm Monitoring Service (DRAMS).ProFicient on Demand-Dedicated Subscription.A short analysis of the data is conducted. You can read along or follow tasks with a provided Minitab file data. This article shows you how to compute process capability using Minitab 18. How to Calculate Process Capability in Minitab 18.It includes sample data to follow along with while a chart is constructed and explained. This is a tutorial on how to create a Pareto chart in Minitab 18. How to Create a Pareto Chart in Minitab 18.Explore this short explanation and an analysis of the results. This tutorial on how to create a P-chart in Minitab includes sample data to follow along with. Explore this straightforward explanation and short analysis of the results. This tutorial on how to create a regression in Minitab includes sample data to follow along with. How to Complete a Regression Analysis in Minitab 18.Operations & Supply Chain Management for the 21st Century.

0 kommentar(er)

0 kommentar(er)